Antep Triangles Protected Geographical Indication

Tuesday, July 5, 2022

No: 360 – Protected Geographical Indication (PGI)

ANTEP TRIANGLES (GAZIANTEP TRIANGLES)

Registrant

GAZIANTEP COMMODITY EXCHANGE

This geographical indication was registered on 13.06.2018 to be protected as of 14.07.2017 under the Industrial Property Law No. 6769.

Registration Number : 360

Registration Date : 13.06.2018

Application Number : C2017/058

Application Date : 14.07.2017

Name of Geographical Indication : Antep Triangles (Gaziantep Triangles)

Product / Product Group : Triangle / Chocolate, sweets and derivative products

Type of Geographical Indication : Protected Geographical Indication (PGI)

Registrant : Gaziantep Commodity Exchange

Address of Registrant : Sanayi Mahallesi 60092 Sok. No:15 Şehitkamil GAZIANTEP

Geographical Boundary : Gaziantep province and districts

Usage Format : The geographical indication Gaziantep / Antep Triangle will be placed

on the product together with the brand of the product.

Product Description and Distinctive Features:

The grape fruit leather is cut into strips with an average width of 6.5 cm and a length of 20-27 cm. Approximately 5 grams, 14-18% of the total triangle mass, triangle filling (also called triangle mixture) consisting of pistachios, starch and powdered sugar is placed in the strips. Antep Triangle is made by wrapping it in a triangular shape. The mass of 1 triangle varies between 32-35 grams.

In the production of Antep Triangles, Antep pistachio that is known to be "Boziç / early harvest / first harvest" (harvested before the fruit ripens, when the color of the fruit is bright green, the color of its shell has not turned completely red while on the tree and is red-green mottled) and is included in the TS 1280 standard and fall into the definitions of "extra", "rank-I" and "rank-II", excluding than Siirt, Halebi and Ohadi varieties, will be used. To fold the triangle, the filling must first be prepared. Gaziantep Triangle filling is prepared by mixing 55-72% of Antep pistachio, 14-18% of powdered sugar and 13-16% of starch in desired proportions. The Antep pistachio used for Antep Triangles will comply with the TS 1280 standard.

Grape fruit leather is used to fill the Antep triangle. Grapes are the grapes grown in the Gaziantep region. Grape variety affects the flavor of the fruit leather. The most preferred grape varieties are the region's grape varieties such as Dökülgen Grape, Hönüsü Grape and Antep İrikara Grape. The grape variety that provides the characteristic flavor to products derived from pekmez in Gaziantep is primarily Dökülgen Grapes. However, due to the fact that other grape varieties have begun to be grown in the region over time, the diversity of grapes used in the making of pekmez, triangle and fruit leather varieties increased.

The fruit leather used in Antep Triangles is made in 2 ways. The first method by directly processing fresh grape juice. The second method is processing the previously prepared pekmez. The only difference between these two methods is that the grape flavor is used fresh in one and ready-made in the other. All other production stages are exactly the same. However, due to the limited shelf life of fresh grapes, processing continues after the grape is turned into pekmez. In this case, it should be specified whether the Antep triangle is made of fresh grape juice or by processing grape juice that has been turned into pekmez beforehand. In addition, it is obligatory to use a copper cauldron during the preparation of sherbet for the fruit leather.

Some regions use for the filling materials specific to their own culture such as walnuts and almonds. In Antep Triangles, the filling is prepared only with Antep Pistachio. The fruit leather used is made from grapes, and components such as walnut pieces are not inserted. The ratio of Antep Pistachios to be included in the final form of the Antep Triangle will be between 8-13%.

Production Method:

Antep Triangle production stages are as follows:

- Starch solution preparation

Wheat starch should be mixed with water to obtain a homogeneous mixture. For this mixture, approximately 18 kg of wheat starch and 24 litres of water is stirred in a cauldron for an average of 30 minutes.

- Preparing the baklava flour and water mixture

Baklava flour should be mixed with water to obtain a homogeneous mixture. For this mixture, approximately 4 kg of wheat flour and 17 litres of water are stirred in a cauldron for an average of 30 minutes.

- Fruit leather preparation

The fruit leather used in Antep Triangles may be made in two ways. The first method is the traditional method and is made by directly processing fresh grape juice. Glucose syrup is not used in this method. Grapes collected in September are transported in plastic crates. Grapes are picked first, that is, the rotten ones are dismissed. Then, the grapes in plastic crates are dipped in water and taken out. In industrial production, the grapes, which are carried on conveyor belts made of perforated stainless steel, are washed by spraying water with a shower system. After the picking is finished, the grapes are washed and placed in iron strainers, filtered, and then placed on a wooden raft. Grape rafts are structures in the form of a rectangular pool made of wood, monolith or, more recently, concrete, on which the grapes will be crushed and juiced. The grapes are first separated from foreign materials. Grapes that are sorted and picked in this way are washed and placed on rafts. After the grapes are placed on the raft, pekmez soil is sprinkled. Pekmez soil, also called Şire soil, is the fragmented form of a stone called Keymık in the region. A person called "fartci", who wears clean boots, begins to step on the grapes. It should be done duly and carefully. The grape juice that exudes first is taken into containers from the upper part of the raft. This is a clearer and lighter colored juice and is called "nasal water". The nasal water is boiled, and thus the fruit leather to be used in the making of Antep Triangles is produced. In its later stages, Antep Pekmez is produced.

The second method is processing the previously prepared pekmez. 150 kg of water is placed in a sufficiently large copper boiler and heated up to 35-40°C. 75 kg of glucose syrup, 15 kg of sugar, 45 kg of pekmez and 3.5 grams of citric acid are put into the same boiler and mixed manually for 35-40 minutes to obtain a homogeneous mixture. The previously prepared starch and flour mixtures are added in and the manual stirring continues until the mixture is boiling. The glucose syrup should be used in accordance with the Turkish Food Codex and Regulations on Confectionery Products.

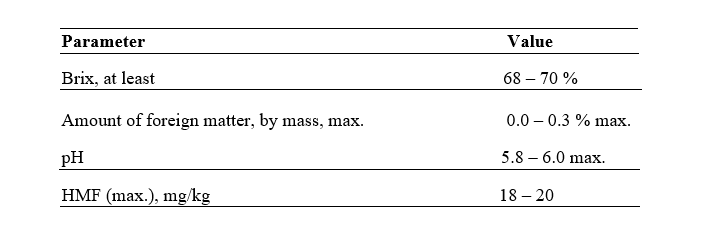

Table 1. Physico-chemical properties of pekmez to be used for the fruit leather syrup

The citric acid used should be odorless and in white powder or crystal structure. The glucose syrup used should be odorless, colorless (transparent) and in the consistency of honey.

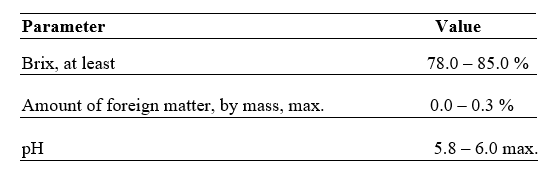

Table 2. Required physico-chemical properties for the glucose syrup

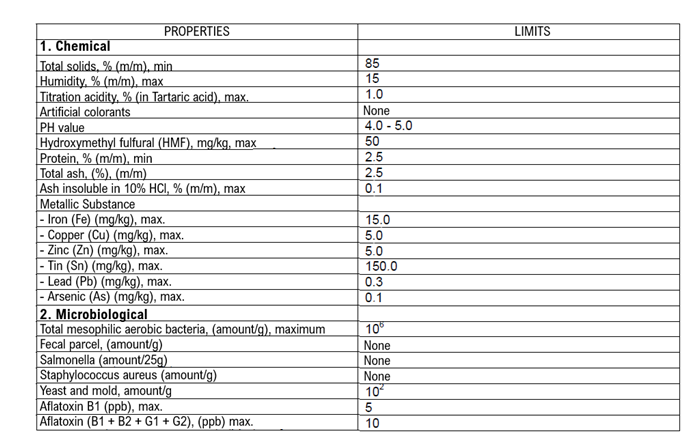

The only difference between these two methods is that the grape flavor is used fresh in one and ready-made in the other. All other production stages are exactly the same. However, due to the limited shelf life of fresh grapes, processing continues after the grape is turned into pekmez. In this case, it should be specified whether the Antep triangle is made of fresh grape juice or by processing grape juice that has been turned into pekmez beforehand. In addition, it is obligatory to use a copper cauldron during the preparation of sherbet for the fruit leather. The upper limits of the chemical and microbiological properties of the grape fruit leather used are provided in the table below.

Table 3. Chemical and microbiological properties of grape fruit leather

- Laying the prepared fruit leather syrup

The prepared fruit leather syrup is laid on cloths. The syrup that is poured on each cloth is spread over the cloth with care, with a wooden trowel, until it is spread evenly across the cloth (2-3 mm). The laid cloths are left on wooden laying boards to rest.

- Pre-cooling in the open air and taking the cloths to the drying room

The cloths are taken to the drying room after resting on the boards for about 30 minutes.

6. Removing and laying the dried fruit leather

The fruit leather, which has completely dried in approximately 20 hours, is removed from the drying room. In order to avoid sticking, the fruit leathers are floured with cornflour.

- Peeling the fruit leather from the cloths and cutting

The cloths are wetted and the fruit leather is peeled off. It is cut by hand with the help of large knives when it reaches the desired thickness and, in order to prevent each peeled fruit leather from sticking to each other, floured with cornflour.

- Making triangles

The previously prepared triangle filling is put into the fruit leather cut into suitable sizes and is folded in a unique way. Since the folding process is a special process, it is done manually. The product is folded in a triangle shape. At the end, its final shape is triangle. In order not to avoid the triangles from unwinding, a process called "dibiklama" is done. Dibiklama is the process that ensures that the triangle shape formed is not destroyed by applying a small amount of honey to the very end of the fruit leather.

- Packaging

The packages must be clean, dry and odorless. They must protect the product well during transportation, storage and marketing, prevent moisture, protect from sunlight, be airproof and not harmful. The inside of the packages to be used must be undercoated with a food-safe material.

- Storage

The product must not be stored in humid and hot places, it must be kept covered and in places where air circulation is sufficient. It should not be kept together in warehouses and vehicles with substances that emit bad odor and may affect the products.

All components used in the production of Antep Triangle and the tools and equipment used in the production of the product must comply with the TGK legislation.

The Production, Processing and Other Transactions to be Performed within the Geographical Boundary:

Antep Triangles should only be made using fruit leathers obtained from grapes grown in Gaziantep. For this, the varieties Dökülgen Grape, Hönüsü Grape, Antep Irikara Grape should be used. It is only produced with Antep Pistachio.

Inspection:

The supervisory authority consists of 5 people, one expert each from Gaziantep Commodity Exchange, Gaziantep Provincial Directorate of Agriculture and Forestry, Gaziantep Gastronomy and Tourism Association, Gaziantep Chamber of Restaurants, Kebab Shops, Pastry Shops, Confectionery Shops and Baklava Shops, and Gaziantep University Fine Arts Faculty Gastronomy and Culinary Arts Department under the coordination of Gaziantep Commodity Exchange.

The supervisory authority inspects;

1 - The production technique of Antep Triangles,

2 - The compliance of Antep Triangles with Turkish Food Legislation and related regulations

3 - The raw materials such as grape juice, pekmez, starch and glucose syrup used in the composition of Antep Triangles and their amounts (and the compliance of the pekmez used with the TGK Grape Pekmez Communique).

4 - Whether the pistachio used for Antep Triangle, although slight superficial damage is acceptable, is rotten and unsuitable for consumption, has visible foreign substances, has visible wetness, has mold and bitterness in taste and has a moisture content of 6.5% by mass or not (and that the content of ash insoluble in hydrochloric acid does not exceed 1 gram per kg, and that there is no foreign taste or odor in the pistachio).

5 - The HMF value in the production phase and in the final product (samples will be taken and internationally accepted analysis methods will be applied in accordance with the TGK Contaminants Regulation and the provisions specified in the relevant legislation for all possible contaminants, especially metal contamination and aflatoxin).

6 - That food additives (except citric acid), flavorants and food components with flavorant properties are not used in the preparation of Antep Triangles.

7 - It conducts inspections periodically, once in 6 months or whenever it's deemed necessary, and in case of complaints, in accordance with the procedure.

The supervisory authority may benefit from or purchase services of public or private institutions, or natural or private entities in charge, during the execution of the inspection. The registrant carries out the legal processes for the protection of rights.

Original text from ci.gov.tr.