Antep Indented Pita Protected Geographical Indication

Monday, July 4, 2022

No: 223 – Protected Geographical Indication (PGI)

ANTEP INDENTED PITA / GAZIANTEP INDENTED PITA / ANTEP PITA

Registrant

GAZIANTEP DEVELOPMENT FOUNDATION

This geographical indication was registered on 31.10.2017 to be protected as of 25.01.2017 under the Industrial Property Law No. 6769.

Registration Number : 223

Registration Date : 31.10 2017

Application Number : C2017/005

Application Date : 25.01.2017

Name of Geographical Indication : Antep Indented Pita / Gaziantep Indented Pita / Antep Pita

Product / Product Group : Pita / Food and Soups

Type of Geographical Indication : Protected Geographical Indication (PGI)

Registrant : Gaziantep Commodity Exchange

Address of Registrant : Sanayi Mah. 60092 No'lu Sokak No: 15 Şehitkamil GAZIANTEP

Geographical Boundary : Gaziantep Province

Usage Format : The phrase Antep Indented Pita / Gaziantep Indented Pita / Antep Pita

and the name of origin emblem are placed on the product itself or on its

packaging. When it cannot be used on the product itself or on its packaging,

the phrase Antep Indented Pita / Gaziantep Indented Pita / Antep Pita and

the emblem of the name of origin are kept in the business in such a way that

it can be easily seen.

Product Description and Distinctive Features:

Antep Indented Pita / Gaziantep Indented Pita / Antep Pita, which has a long history and is a part of Antep cuisine, is an oval shaped flat bread approximately 20 cm wide, 39 cm long and approximately 1 cm thick (Picture 1). Due to the indentations made on the dough, there are indentation spaces on the surface of approximately 1.35 x 1.40 cm and generally homogeneously distributed.

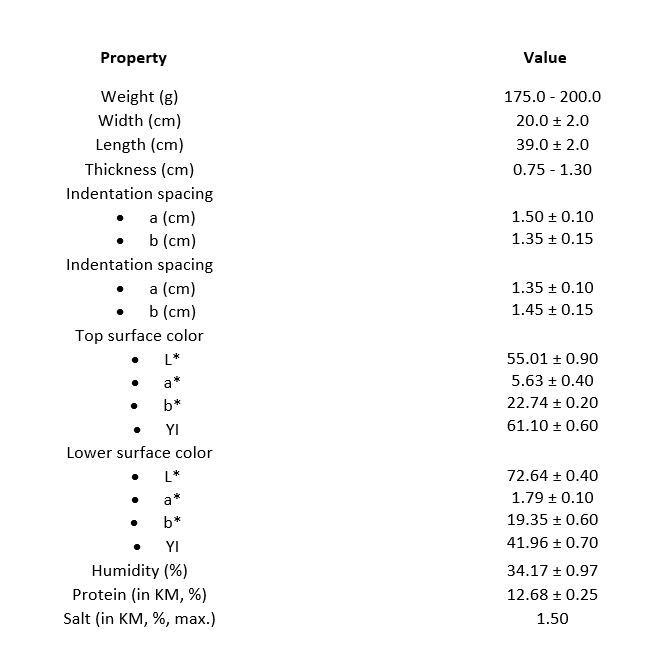

The physical and chemical properties of Antep Indented Pita / Gaziantep Indented Pita / Antep Pita are given below and the color values were calculated using the Hunter Lab Colorimeter.

Picture 1. Antep Indented Pita / Gaziantep Indented Pita / Antep Pita

Table 1. Physical and Chemical Properties of Antep Indented Pita / Gaziantep Indented Pita / Antep Pita

Consumption and serving method: Antep Indented Pita / Gaziantep Indented Pita / Antep Pita is made by demand in neighborhood bakeries and consumed hot.

Neighborhood bakeries hold an important place in Gaziantep. Antep Indented Pita / Gaziantep Indented Pita / Antep Pita is produced only in these bakeries and by experienced experts in this field. Pita are bought and consumed as a meal. In places such as restaurants, Antep Indented Pita / Gaziantep Indented Pita / Antep Pita is served as local bread. In addition, Antep Indented Pita / Gaziantep Indented Pita / Antep Pita is consumed with dishes such as kebab, roasted eggplants, pepper and eggplant kebab by making a wrap.

Bakeries are small family businesses. Two-thirds of the breads produced in these bakeries are Antep Indented Pita / Gaziantep Indented Pita / Antep Pita, and one-third open bread. Stone ovens are used in these enterprises. Stone ovens are uniquely designed in the shape of a sphere in order to keep all the heat of the wood fire in the oven. Neighborhood bakeries, many of which use wood fires, are kept open all day. Pita do not come into direct contact with fire. The fire burning on the side heats the stone on which the pita is placed. While the stone gives warmth from the bottom of the pita, the fire heats the upper part of the pita in the oven, which looks like a hemisphere.

Properties of ovens: The base is a semicircle. It is shaped like a quarter sphere. From bottom to top, there is red soil, insulation materials (lime, iron powder, glass wool), salt, glass powder and sphalerite, respectively. In the dome structure, there is stone, red soil, salt, brick and concrete. There is an entrance to the oven from where pita is placed. This entrance is approximately 1 m wide and 70 cm high. Just above this opening is a chimney to let the smoke out. There is also a bellow that let air in (in wood ovens). About 40% of the semicircular base is reserved for fire. This area has a tripod at the base for easy removal of ash. Ovens are designed in this way to keep the temperature for a long time. An oven maintains its temperature for 12 hours even after it is turned off, successfully keeping pests out. The sphalerite on the bottom has a suitable structure for the heat to be distributed evenly and for all the breads to be cooked to the same degree. Usually wood is burned in ovens as fuel. However, the use of natural gas has become widespread in recent years. The type of fuel used does not change the flavor of the pita.

One of the distinguishing features of Antep Indented Pita / Gaziantep Indented Pita / Antep Pita is the method of indention. It is indented with the hand skills of the expert bakers of Gaziantep to increase the surface area for the homogeneous distribution of the heat during the baking of the pita. In this way, while the top of the pita stays brown, the bottom parts are cooked sufficiently and the aroma of the pita is not lost. Thus, the distance between the indentions, the depth and the cross show their effect during cooking. Antep Indented Pita / Gaziantep Indented Pita / Antep Pita should be slightly brown in color (the indented swelling parts) while the base should be less brown and/or cooked.

Production Method:

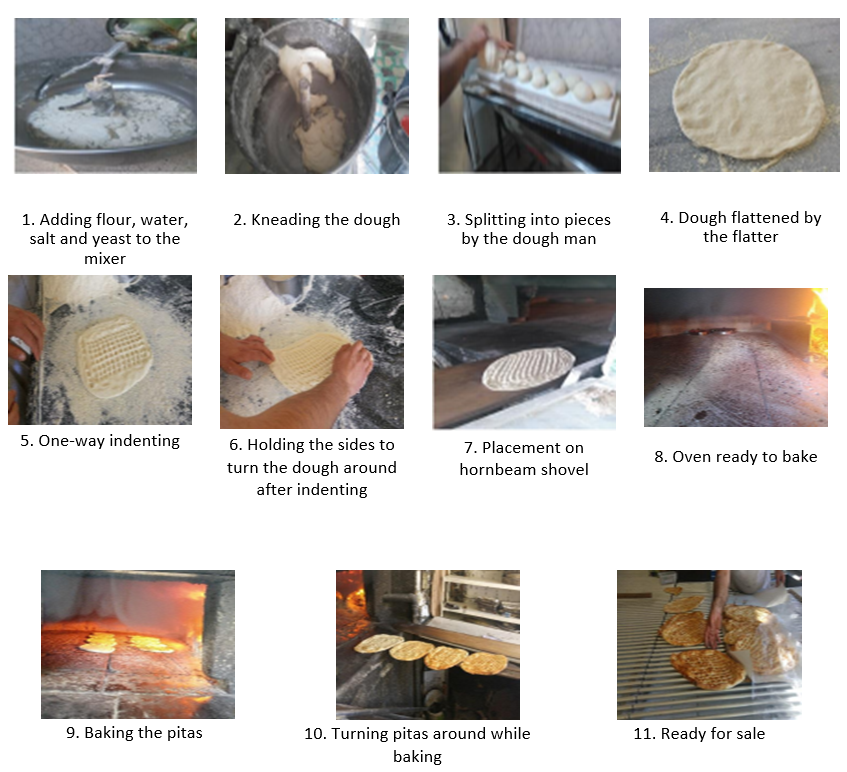

In the production of Antep Indented Pita / Gaziantep Indented Pita / Antep Pita, bread wheat flour and/or whole wheat flour defined in the Turkish Food Codex Wheat Flour Communique is used. Dough is prepared and kneaded with the basic ingredients (flour, water, yeast and salt). The dough is relatively runny. It is made from a sack (50±1 kg) of flour, approximately 30±1 liter of water (until the dough thickens under the supervision of a baker), a packet of yeast (500±50 g) and salt (20-30 g). Dough making takes an average of 30 minutes, depending on the season, including resting. The waiting time is shorter in summer and longer in winter. Although the time is determined by the experience of the chef, they are approximately 20-25 minutes in summer and 30-35 minutes in winter. Yeast can be used less in summer and more in winter (500±50 g in summer, 750±50 g in winter). The resting time (fermentation) is determined by the baker depending on the amount of yeast and temperature. This fermentation takes place in mass in the kneader tank. Pieces in the form of balls are taken from the fermented dough according to the determined weight. While the kneading process is done in the kneader, all other processes are done manually. The ball-shaped dough is left to rest for 5-10 minutes. After the rested dough is flattened with a roller, the slurry mixture, consisting of flour and water prepared in a separate bowl, is spread on the dough in a thin layer. Then, the dough is indented. The cooking process takes about 3-4 minutes. The indented parts of the pitas with thicker (1.5-2 cm) unindented edges are 0.5-0.75 cm thick. Baked pitas are offered for sale, covered with a cloth so that they do not dry out.

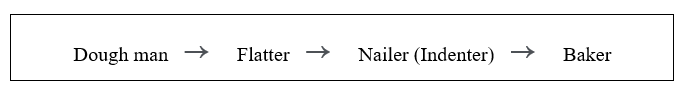

Figure 1. Workflow order of Antep Indented Pita / Gaziantep Indented Pita / Antep Pita masters

Dough man (Hamurkâr): They are responsible for preparing the dough, dividing it in equal and suitable weight (150-170 g) and final resting processes. They ensure that the dough is kept at the appropriate temperature, covered with a damp cloth (if it's summer), floured and transported.

Flatter (Tapçı): They are responsible for dividing and flattening the dough coming from the dough man again, if necessary. Ensuring the appropriate thickness is very important for indentation. They work on the dough of appropriate size and thickness (50-60 cm in diameter and 1.5-1.7 cm in thickness) and sends it to the indenting master. When an apprentice is hired, they first observe the flatter and start learning from there. They work side by side with the indenter. The person who gets the job works as a flatter for at least 3 months. They then work as an indenter assistant for at least 3 months. At the end of the total period of 6 months, they can become a flatter. It is considered appropriate for a flatter to become a dough man after at least 6 months of experience.

Nailer (Indenter / Tırnakçı): The most important one is the indenting master. They are the person who maintains the indenting method (called "nailing") that has been passed on for centuries with their dexterity. The indenting master increases the surface area of the pita and ensures that the bread is baked homogeneously.

Baker (Pişirici): They are responsible for arranging the pita dough prepared by the indenter on the shovels, placing it in the oven and monitoring its baking. They check the temperature of the oven and the baking time of the dough. They play an important role in giving the surface its color with the placements close to the fire. They spin the pieces of dough after a certain period of time and make sure that they bake evenly from every side.

Indenting method: The indenting method and the cooking technique of the Antep Indented Pita / Gaziantep Indented Pita / Antep Pita is its most unique and most important distinguishing feature. The more uniform and flat the dough from the flatter, the better. It is undesired for the dough to be too thick or too thin. The indented first feels the dough with his hand to see the thickness of the dough. This information is used to determine the strength of the indentation. If the dough is thin, the force is reduced; if it is thick, it is hit harder. Indenting is done using both hands, with 8 fingers excluding the thumbs. Beforehand, hands are wetted with water. The dough that comes in a round shape is first indented with fingertips all over. Indenting is done about 12 times consecutively and quickly. Not the nails, but the protrusions of the fleshy part in front of the nails are struck into the dough. The dough should not be pierced. Then, the dough is held from the upper right and lower left parts of the indented axis and rotated 180°. In this way, the indented part goes from vertical to horizontal. Thus, both an oval shape is given and the untouched sides are ensured to get indented. According to the master, 15-17 indentations are made again on the vertical axis (Figure 2). Thus, the knitting pattern is completed. Finally, the master gives the bread an oval shape by holding the upper right and lower left corners of the bread. In this way, the corners are also indented. Antep Indented Pita / Gaziantep Indented Pita / Antep Pita takes a homogeneous and neat form.

Depending on the size of the indenter's hands, sometimes 2 turns can be made on the same axis. This process increases the number of gaps on the surface of the bread. The master can change the number of indentations according to his own experience. However, this is very rare.

Figure 2. Indentation method

Storage conditions and shelf life: Pita are generally consumed hot. During peak hours, many bakeries accumulate pitas. Other times, the pita is cooked upon request.

The accumulated pitas are kept at room temperature under a cotton cover to keep them warm and not lose moisture. The product should not be stored under the sun, in extremely hot-cold and/or humid environments.

The shelf life of the product is 3-4 hours depending on the storage conditions. Afterwards, there is no microbiological, physical or chemical change in the product in terms of human health, but it is not preferred by the consumer because it generally loses its sensory properties.

Figure 3. Production of Antep Indented Pita / Gaziantep Indented Pita / Antep Pita

The production, Processing and Other Transactions to be Performed within the Geographical Boundary:

Antep Indented Pita / Gaziantep Indented Pita / Antep Pitae, which has a long history and requires mastery skills, has a reputation link with the region. For this reason, all stages of production must take place within the specified geographical boundary.

Inspection:

The supervisory authority is formed under the coordination of Gaziantep Commodity Exchange and with the participation of at least 3 representatives from Gaziantep Commodity Exchange, Gaziantep Metropolitan Municipality, Gaziantep Pideciler Simitçiler and Yufkacılar Chamber, Gaziantep Provincial Directorate of Agriculture and Forestry, Gaziantep University and Şehitkamil Chamber of Agriculture. Inspections are carried out regularly once a year, and whenever needed or upon complaint.

The criteria for the inspection are given below.

- The flour used in production is bread wheat flour and/or whole wheat flour as defined in the Turkish Food Codex Wheat Flour Communiqué.

- Ovens to have appropriate features (materials in the oven, oven dimensions).

- The appropriateness of the dough (processing order of the pita masters, the materials used for the dough and their quantities, dough making time).

- The indenting/nailing method (number of indentations, indentation spacing).

- Appropriateness of the baking process (temperature, time).

- The appropriateness of the Antep Indented Pita / Gaziantep Indented Pita / Antep Pita in terms of appearance, size and aroma.

- If necessary, taking a product sample from the production site and analyzing its physical and chemical properties in the laboratory environment.

- Appropriateness of the use of the phrase Antep Indented Pita / Gaziantep Indented Pita / Antep Pita and the logo of the geographical indication

The supervisory authority may benefit from or purchase services of public or private institutions, or natural or private entities in charge, during the execution of the inspection. The registrant carries out the legal processes for the protection of rights.

Original text from ci.gov.tr.