Antep Freekeh Protected Designation of Origin

Monday, July 4, 2022

No: 244 – Protected Designation of Origin (PDO)

ANTEP FREEKEH

Registrant

GAZIANTEP EXCHANGE COMMODITY

This geographical indication was registered on 24.11.2017 to be protected as of 18.01.2017 under the Industrial Property Law No. 6769.

Registration Number : 244

Registration Date : 24.11.2017

Application Number : C2017/007

Application Date : 18.01.2017

Name of Geographical Indication : Antep Freekeh

Product / Product Group : Freekeh

Type of Geographical Indication : Protected Designation of Origin (PDO)

Registrant : Gaziantep Commodity Exchange

Address of Registrant : Sanayi Mah. 60092 No’lu Sokak No:15 Şehitkamil GAZIANTEP

Geographical Boundary : Gaziantep Province borders

Usage Format : Marking

Product Description and Distinctive Features:

Wheat that is smoked/burned in the field without husking while it is still green is called freekeh (firik). Freekeh is a local product similar to bulgur and rice in appearance, green-brown in color and generally made from durum wheat. It is harvested when the grains start to harden as the wheat ripens in the field, but the spike is green. In the fire obtained by burning the wheat stalks, the grains are burned. The awned part around the grains is burned to separate them from the grain. During this process, a unique soot taste and odor occur in the grain. The grains are blown in the wind to separate them from the burned parts. Thus, grains become soft enough to be crushed with teeth and separated from their outer skin (husk). This product, which has a unique taste and smell of soot, and whose color varies between yellow and green, is called freekeh.

Generally, Triticum durum wheat, and sometimes Triticum aestivum wheat, is preferred for freekeh making. Both types of freekeh are made in Gaziantep, but Antep Freekeh is made from Triticum durum wheat grown in Gaziantep. Although the freekeh produced in different regions are close in terms of shape and nutritional values, there are regional differences in terms of cooking quality (hardness, integrity), color and sensory.

Freekeh is a more expensive product than wheat and bulgur. For this reason, it is produced by farmers using traditional methods, especially in regions where it is consumed. Fructooligosaccharide, a fructose-rich polymer, is abundant in freekeh. Fructooligosaccharides have biological functions such as antitumor, immunostimulating and prebiotic effects. In addition, they have a positive effect on the absorption of many minerals. For this reason, unripe wheat is considered a functional food.

Picture 1. Antep Freekeh ready to be consumed

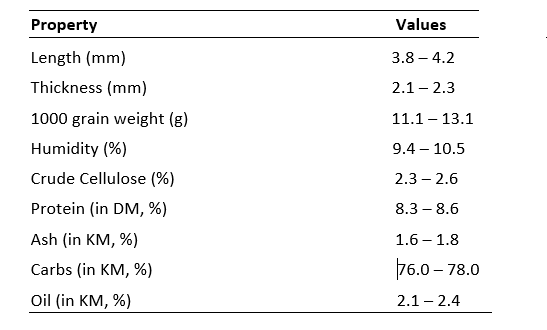

Physical and Chemical Properties:

The physical and chemical properties of Antep Freekeh are given in Table 1. It contains small amounts of vitamins A, B1, B2, C and E, as well as potassium, magnesium and calcium.

During the ripening process of wheat grain, its physical properties and chemical composition change. In the study conducted on durum wheat, it was observed that while the moisture and ash content decreased, the grain weight and hardness increased. However, although there is no significant change in the amount of protein in this process, the amino acid contents may change.

The most important quality parameters of freekeh are its unique sooty aroma and yellow-green color. These features are achieved with the appropriate "burning technique" and then the correct "drying" process depending on the wind and temperature factors suitable for the product of the region. In order for this technique and process to be carried out properly, it is necessary for one to master the job after having been a freekeh producer for at least 3-4 years.

Table 1. Physical and Chemical Properties of Antep Freekeh

The use of the product and its differences from similar products:

Freekeh is consumed in meals (rice etc.) and as a snack. Today, it is released in the market in packages. Freekeh can be considered in the same category as bulgur and groats, but it is 3-4 times higher in unit price. The product that freekeh is most similar to was said to be bulgur. Although bulgur and freekeh are similar in terms of raw material and usage, there are differences in terms of nutritional values and production method. While bulgur is produced from ripe wheat as a semi-cooked product, freekeh is produced from unripe wheat by burning it. In addition, the peeling process of bulgur is done with a peeler, while the outer skin of freekeh is separated by burning instead of peeling.

Freekeh is generally produced by wheat farmers for their own use or by small-scale enterprises. Its consumption is similar to bulgur. Freekeh is mostly used in pilaf making like bulgur or rice. Freekeh pilaf is an important part of Gaziantep cuisine. Freekeh pilaf is prepared with freekeh, which is collected in the field while the wheat is ripe and green, and by burning/processing/smoking in accordance with its technique, its color is in the yellow-green range and has a unique taste.

The way Antep Freekeh is made and used in Gaziantep, and its raw material are its main distinguishing features. First of all, freekeh is made from the hard, unripe durum wheat in Gaziantep. Raw spikes of wheat collected as products are burned in a fire while they are green. For burning, there must be branches of the olive tree and/or the wood of the vine tree. Since the amount of olive and vine trees is high in Gaziantep, these two tree species have been used for incineration in the production of freekeh for a long time. These two burning ingredients help to create the unique taste of Antep Freekeh. Antep Freekeh is between yellow and green hues, preferably closer to green. Generally, the drying process is not done under direct sunlight in order not to lose the green color. These features basically constitute the distinctive features of Antep Freekeh. In addition, freekeh, which has been grown in the region for centuries, has completely entered the gastronomy of Gaziantep and is used in many recipes.

Production Method:

In a study on the maturation process of wheat grain, the most suitable time for harvesting for freekeh production was determined as the 2-week period between the end of the milk stage and the beginning of the dough stage. Moreover, the most delicious freekeh is made from hard and large durum wheat. The most important reason why the harvest period is at the end of the milk stage and the beginning of the dough stage is the high amount of simple sugars in this period.

In Gaziantep, it is harvested in a period of about 2 weeks when the height of the spikes is around 15 cm from the ground and the humidity is around 45%. The freekeh harvested at this time gives the best results in terms of flavor and scent.

Harvest time is key to a quality product. If harvested too early, the grains lose their integrity. If harvested too late, it will prevent the unique color and aroma from forming. Wheat grown for the purpose of making Antep Freekeh is harvested approximately 1 month before the normal harvest time. For Gaziantep, this period is generally the last 2 weeks of May. Grains harvested to make freekeh have a moisture content of about 40-45%. According to the fullness of the wheat grain, the harvest period is determined by the experienced farmers. The fullness of the wheat grain depends on whether the field is irrigated or whether the season is rainy. Another factor affecting the harvest time is the ending of the the pluvial. Looking at the meteorological data, it will be seen that this period coincides with the end of May. During this period, the sprouts of wheat are cut. The sprouts are burned in a wood fire.

Incineration may vary depending on the amount of production. If the amount of production is large, a large wood fire is prepared and a sieve is placed on top. Green wheat is roasted on the sieve by stirring. If the production amount is low, it is burned in bunches by hand and stirred continuously. After the smoke is white and the smell of burning is present, it is understood that Antep Freekeh has reached the "burning consistency", the roasted wheat is taken from the fire, spread on the cover laid in the shade of the trees and left to dry and cool (1-3 days). After a while, the grains and the burned parts are separated with the help of the wind. Some parts are separated by rubbing in the palm. After the smoking/burning/processing operations, the product is not left under direct sunlight, so that the unique yellow-green color of the freekeh is preserved. Drying time is adjusted by experience according to the temperature and wind. This period is set as a minimum of 1 and a maximum of 3 days.

In earlier times, the drying time was determined according to the ease of the separation of the grain from the burned parts by way of hands after drying. The dry product thrown into the thresher was separated from the stalks. Before the thresher, the burned parts and the grains were separated from each other by the method of tossing with the help of the wind. In this way, burnt fiber was obtained as grain. The grains were left to dry in the wind and shade again in a thin layer. In Gaziantep, this period was applied as 2 days on average (approximately 15% humidity). Then, they were drawn in the mill according to the demand and classified as coarse fiber, fine fiber, flour and bran.

Antep Freekeh is produced with a unique flavor and aroma as a result of the combination of the meteorological values of Gaziantep suitable for its production and the mastery and experience of Gaziantep farmers.

Important details:

- Unripe wheat that will not burn in the fire is not considered freekeh.

- Stove burning, which has become widespread in recent years, spoils the taste. These products do not have the traditional Antep Freekeh flavor..

- For the wood fire process, only the branches of the olive tree and/or the wood of the vine tree should be used. Because the flame that emerges in the burning process, in which only these two burning materials are used, creates the unique aroma of Antep Freekeh. Since the pine tree is very sooty, it is not used for incineration.

- Farmers are the ones with the knowledge and familiarity of the production of freekeh. Burning requires skill.

- In the interviews with the local farmers, it was stated that the method has not changed, although it is not known how long freekeh has been produced for.

- The fuller the wheat, the better the freekeh.

- The flavor of the irrigated field is better.

- Antep Freekeh is between yellow and green color tones and cannot be dried directly under the sun.

- Antep Freekeh is made only from durum wheat.

- Antep Freekeh loses 40% of its weight during the production process. Quality grains are slightly carbonised, hard, raw, green in color and free from residues.

- Type of wheat, harvest time and burning process are very important for the production of freekeh. Mastery in the incineration process helps freekeh gain its distinctive flavor. On the other hand, the light wind during incineration helps burn only the shell part of the grain and leave no residue afterwards. In addition, since the humidity is high during incineration, the smoke is white in color and there is no intense soot.

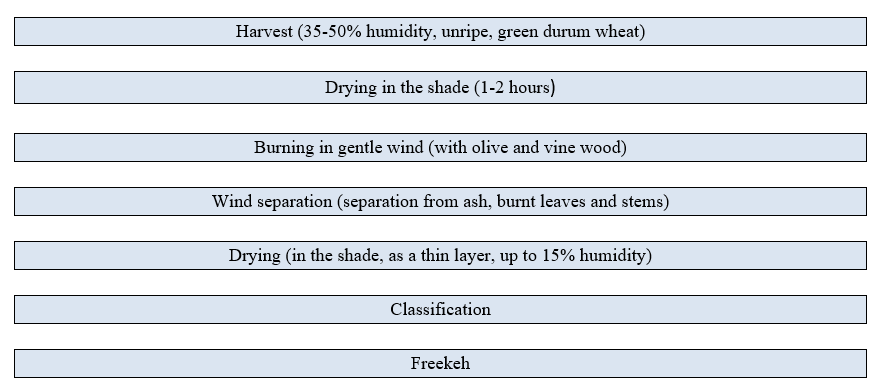

Antep Freekeh production method used in local businesses is shown in Figure 1.

Figure 1. Antep Freekeh production method in local businesses

Inspection:

Inspections are coordinated by Gaziantep Commodity Exchange; Gaziantep Commodity Exchange, Gaziantep Metropolitan Municipality, Gaziantep Provincial Directorate of Agriculture and Forestry, Gaziantep University and the Sehitkamil Chamber of Agriculture are carried out by a supervisory authority of at least 3 people, each of whom is knowledgeable about the product.

The supervisory authority conducts inspections at least once a year. In addition, in case of need, upon complaint or suspicion, it can always meet and conduct inspections.

Audits will consist of two main elements. The first main element is the inspection of the production method of the product. The second main element is the inspection of product features.

A) Inspection of production method

- Whether the type of wheat used is appropriate

- Whether the time of the harvest period is appropriate

- Whether the incineration process is done properly (the freekeh should not be burned)

- Humidity (whether the drying duration and method are appropriate)

- The type of wood used in the incineration process (must be the branch of the olive tree and/or the wood of the vine).

B) Checking the features of the product

- Whether the product color is appropriate

- Whether the product aroma is appropriate (the presence of a distinctive soot odor)

- Whether the physical and chemical properties are appropriate (will be sent for analysis if needed).

The supervisory authority may benefit from or purchase services of public or private institutions, or natural or private entities in charge, during the execution of the inspection. The registrant carries out the legal processes for the protection of rights.

Original text from ci.gov.tr