Antep Cheese Protected Geographical Indication

Tuesday, July 5, 2022

No: 356 – Protected Geographical Indication (PGI)

ANTEP CHEESE/GAZIANTEP CHEESE/ANTEP SIKMA CHEESE

Registrant

GAZIANTEP EXCHANGE COMMODITY

This geographical indication was registered on 04.06.2018 to be protected as of 20.04.2017 under the Industrial Property Law No. 6769.

Registration Number : 356

Registration Date : 04.06.2018

Application Number : C2017/032

Application Date : 20.04.2017

Name of Geographical Indication : Antep Cheese / Gaziantep Cheese / Antep Sıkma Cheese

Product / Product Group : Cheese / Cheese

Type of Geographical Indication : Protected Geographical Indication (PGI)

Registrant : Gaziantep Commodity Exchange

Address of Registrant : Sanayi Mah. 60092 Sok. Bina no:15 27170 Şehitkamil GAZIANTEP

Geographical Boundary : Gaziantep province

Usage Format : The name of the Antep Cheese geographical indication can be used on the

product together with the brand. In addition to the other information that is

on the packaging of the product, if any, the logo is also given below.

Product Description and Distinctive Features:

Antep Cheese is a local cheese produced in Gaziantep and bearing the name of the same province. Antep Cheese is a type of cheese traditionally made from the milk of domestic ovine & caprine animals grazed in the pastures of Gaziantep. It is also called “pişken” or “kelle” in Gaziantep.

It is a semi-hard cheese produced and consumed raw (without brining) or ripened in brine. In production, only sheep or goat milk may be used, as well as a mixture of 50% sheep and 50% goat milk.

Physical and Chemical Properties of Antep Cheese:

The appearance of Antep Cheese is homogeneous, non-porous, smooth, tight and clean. It does not crumble when cut, and is semi-hard, flexible, easily dispersed in the mouth. It leaves a squeaky feeling in the mouth when chewed. Its color is between gray and white. Antep Cheese has an irregular oval (palm-like) shape. This shape is due to the fact that cheeses are traditionally shaped in the palm of the hand. The distance between the two long ends of the oval shape is 6 to 10 centimeters.

Chemical properties of Antep Cheese:

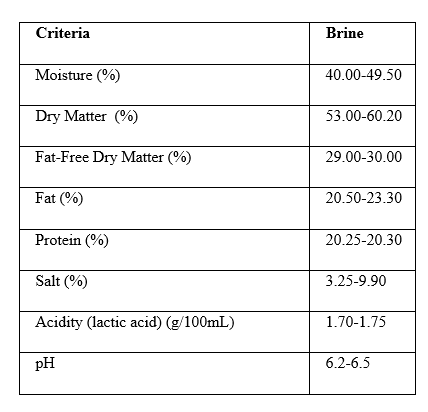

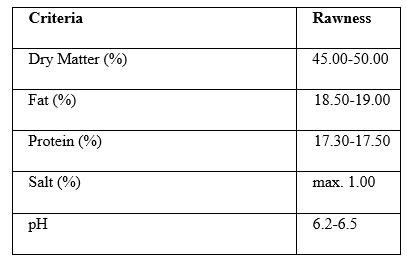

Table-1: Values for Brined Antep Cheese

Table-2: Values for Raw Antep Cheese

Reducing the fat content of the raw milk used in Antep Cheese making affects the physical properties and aroma of the cheese. Thus, while making Antep Cheese, the fat ratio should not be reduced and should remain within the limits specified above.

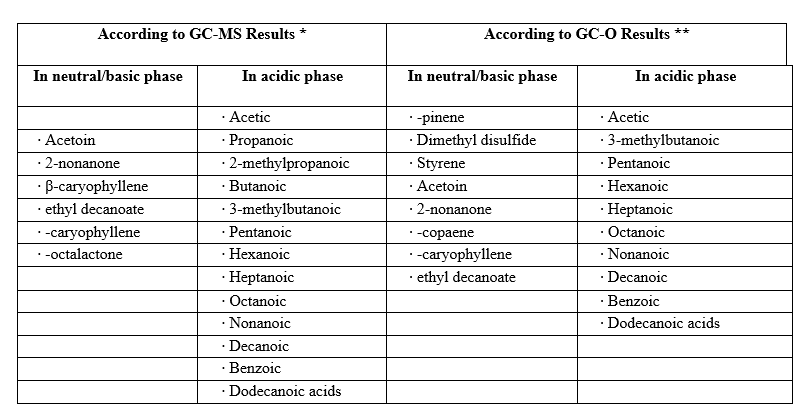

49 different aroma active ingredients were determined in Antep Cheese. The number of substances that affect the aroma is 64.

A total of 48 volatile compounds belonging to seven different groups, including ketones, esters, alcohols, lactones, terpenes, aldehydes and aromatic hydrocarbons belonging to the neutral/basic fraction of Antep Cheese, were determined.

2 ketones were determined in Antep Cheese:

∙ 3-hydroxy-2-butanone (acetoin)

∙ 2-nonanone

3-hydroxy-2-butanone is a ketone with a “butter” flavor, formed by citrate metabolism by lactic acid bacteria and reduced by the enzyme diacetyl-reductase. 2-nonanone is the compound that creates the "fruity" and "hot milk" flavor. Due to these compounds, Antep Cheese has fruity and warm milk aroma flavors.

The highest number of compounds in the neutral/basic fraction of Antep Cheese are esters, which there are a total of 19 of and appears as ethyl decanoate (composed of 12 carbon atoms). Since this ingredient gives the food a "grapey" flavor, Antep Cheese has a grape flavor.

3 alcohol components were detected in Antep Cheese;

∙ Ethanol

∙ 3-methyl-1-butonal

∙ 2-phenylethanol

There are 4 lactone components in Antep Cheese: hexalactone, octalactone, undecalactone and dodecalactone. The common component of octalactone is present in Antep Cheese.

There are 2 aldehydes in Antep Cheese.

∙ nonanal

∙ 2-4 hexadienal

There are 8 hydrocarbon components in Antep Cheese.

There are a total of 9 terpene components in Antep Cheese. Since terpenes are in the structure of green fodder plants, they pass into the milk of animals that eat in meadows and pastures green grass and cheese produced from their milk. This gives a clue about the geography where the cheese milk is obtained and the nutrition of the animal. Antep Cheese contains common terpenes of β- and α-caryophyllene. In addition, these components are found in aromatic forage plants such as thyme and mint that grow wild in the mountains.

There are 17 free fatty acids in the acidic fraction of Antep Cheese. Branched fatty acids are characteristic fatty acids of sheep and goat cheeses.

In neutral/basic phase; α-pinene, dimethyldisulfite, styrene, acetoin, 2-nonanone, α-copaene, caryophyllene and ethyl decaonoate components characterize the aroma profile of Antep Cheese.

Common aromatic components in Antep Cheese;

* GC-MS: Gas chromatography-Mass spectrometry

** GC-O; Gas chromatography-Olfactometry

Production Method:

Raw milk is used in the production of Antep Cheese and it is fermented with abomasum, chemical yeast or fig milk at udder temperature (approximately 35°C) where it is milked. In early times, milk was fermented only with fig milk. Fermentation of raw milk with fig yeast is rare today, but it is usually performed by shepherds during grazing on the mountains. The underripe form of the fig is called “kerik” (in the local dialect, “kerrik”), and the stiff, white fig milk obtained during the removal of the underripe fig branch is used as yeast. During the fermentation stage, 4 or 5 keriks are taken for ½ liter of raw milk and distilled into the milk. Fermented milk is left for 1-2 hours to coagulate. The resulting clot is transferred to cloth bags without harm. The bags can be placed on a sloping surface and left to drain on their own, or is drained by placing a stone on top. The pressure should be at a rate ranging from 1/10 to 1/5 of the weight of the milk used in cheese making. The filtration process is continued until the curd is completely removed. When the curd is hardened, pieces are taken from the curd with a spoon and placed in small strainer bags made of cheesecloth called “sesbezi (sheer cloth)” or “cibinlik (mosquito net)”. The opening of each bag is slightly bent and squeezed to lubricate the outside of the cheese.

The whey drained from the curd is boiled in a cauldron. Then the cheese pieces in the bags are thrown into the whey, the temperature of which may vary between 80°C and 90°C, and boiled for 1 minute. Pieces of cheese are taken from the cauldron and placed on trays and left to cool. When it reaches a temperature that will not burn the hand, the cheeses are shaped by squeezing between the palms and during this squeezing process, the boiling water is also removed.

The obtained cheese pieces ("kelle") are salted in two different ways. In one method of salting, in which the cheese is desired to be stored for a long time and is generally called winter salting, dry rock salt is sprinkled on the cheese pieces. The salt content varies between 2% and 4%. After sprinkling with dry salt, the cheese pieces are kept in salt for 2 days with regular stirring. In the meantime, some more bitter whey comes out of the cheese. At the end of two days, the waste whey is removed and the cheese pieces are taken from the salting container and put into brine with a salt content of 15% to 20% and offered for sale.

In cheese that will be consumed in a short time (10-15 days) and is usually made in summer, dry rock salt is used again. However, the rate of salt used in this salting method varies between 1% and 2%. Cheese pieces are kept in dry salt for 2 hours with regular stirring. At this stage, some whey is released. At the end of this period, the waste whey is removed and the cheese pieces are taken from the salting container and stored in the cooler (3-5°C) without brine. This practice is generally used by families living in Antep region for their own consumption.

In traditional production, fresh raw eggs and olives are used to adjust the salt ratio of the brine. If the cheeses are to be stored for the winter, the salt ratio of the brine is desired to be more intense, so the salt ratio is adjusted using raw eggs. After the brine is prepared, a fresh raw egg is thrown into it, if any part of the egg (as big as a large coin) rises to the surface, the salt ratio is appropriate. The brine prepared for cheeses to be consumed immediately has a lower salt concentration. Thus, olives are used instead of eggs in the salt adjustment of the brine of the product to be consumed sooner.

Pickled cheeses are kept in cold storage (3-5°C) for 2-3 months after soldering the tins and then released for consumption. Antep Cheese is a durable cheese and can be stored for 2-3 years.

Antep Cheese has a semi-hard and salty structure. When it is desired to be consumed, it is kept in cold water for about 8-10 hours.

Inspection:

Antep Cheese Inspection Board, under the coordination of Gaziantep Commodity Exchange, consists of 3 experts, one each from Gaziantep University, Faculty of Engineering, Food Engineering Department, one person from Şehitkamil Chamber of Agriculture, Gaziantep Provincial Directorate of Food, Agriculture and Livestock, and Gaziantep Metropolitan Municipality.

The supervisory authority may take samples from the places where Antep Cheese is produced and sold, and subject them to analysis in an official laboratory that performs food analysis. The conformity of the chemical composition, physical and textural structure of the products taken as samples to the registration certificate is inspected. If the chemical, physical and textural analyses do not give a sufficient idea about the suitability of the product for registration, aromatic components are determined. The supervisory authority carries out the actions arising from the legislation about the productions that do not comply with the registration certificate and opens the lawsuits.

The supervisory authority will conduct a routine inspection at least once a year. In case of a complaint, the supervisory authority may repeat this inspection indefinite times. It is also among the duties of the supervisory authority to take minutes after the audits and to prepare an audit report every year.

The supervisory authority may benefit from or purchase services of public or private institutions, or natural or private entities in charge, during the execution of the inspection. The registrant carries out the legal processes for the protection of rights.

Original text from ci.gov.tr.